Woodworking is not just a craft; it’s an art form that has been perfected over centuries. At the heart of this timeless craft lies the intricate practice of wood joinery. From the humble dovetail to the elegant mortise and tenon, wood joinery techniques have been passed down through generations, each generation adding its own innovations and refinements.

Mastering wood joinery involves understanding various joint types, their specific applications, and the right methods for creating strong, effective connections in wood.

As you proceed, this guide will walk you through the essential joints, from the straightforward to the more complex, providing practical advice for their application. Whether you’re reinforcing a table or crafting a decorative piece, these basics will set the foundation for your woodworking success. Keep reading to start your journey into the art of wood joinery.

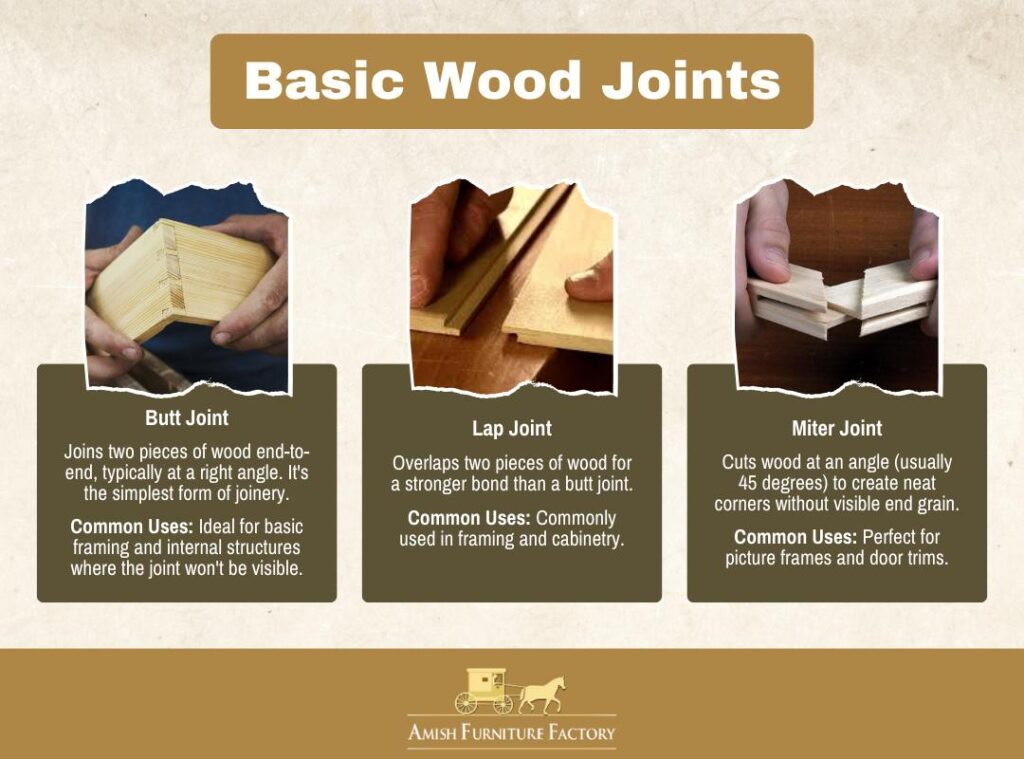

Basic Wood Joints

Woodworking is an art and a science, where the choice of joint can make or break a project. Whether you’re someone looking to build sturdy, long-lasting structures or a hobbyist aiming to refine your craft, understanding basic wood joints is crucial. Let’s dive into some of the fundamental joints that are essential for anyone working with wood.

Butt Joint

The butt joint is the simplest form of wood joinery you’ll come across. It involves joining two pieces of wood end-to-end, usually at a right angle. While this joint may not boast high strength, its simplicity makes it a popular choice for beginners and for projects where aesthetics are not the primary concern.

To make a butt joint, you just need to cut the wood to the desired length and then glue, nail, or screw the pieces together. This type of joint is great for basic framing or internal structures where the joint won’t be visible. However, keep in mind that its strength is limited, so it’s not ideal for load-bearing applications. For added stability, you can reinforce a butt joint with dowels or fasteners.

Lap Joint

The lap joint, a step up in complexity and strength from the butt joint, involves overlapping two pieces of wood. This joint is more robust and is commonly used in framing and cabinetry. The overlapping area provides a larger surface for gluing, offering a stronger bond than a butt joint.

Creating a lap joint typically involves removing half the thickness of each piece of wood at the joining point so that when they overlap, the combined thickness equals that of a single piece. This joint not only provides better strength but also maintains a relatively flush and smooth appearance. It’s a versatile joint that can be adapted for different applications, making it a useful skill in your woodworking arsenal.

Miter Joint

A miter joint is a more aesthetically pleasing joint, often used in picture frames, door trims, or anywhere you need a neat corner without visible end grain. It involves cutting two pieces of wood at an angle (typically 45 degrees) and joining them.

To create a miter joint, precision in cutting the angles is key. When done correctly, the joint forms a perfect right angle, making it ideal for frames. However, because the joint relies mostly on wood glue for its strength, it’s not as sturdy as some other joints. For added strength, you can reinforce it with nails or spline inserts, especially in larger frames or installations.

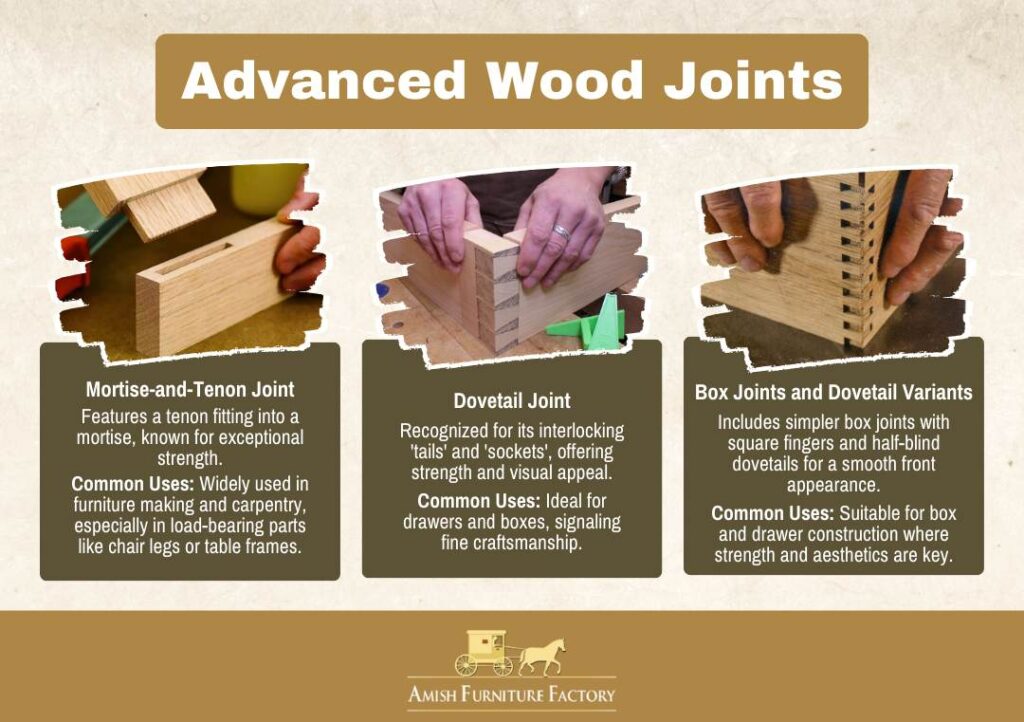

Advanced Wood Joints

After mastering the basics, it’s time to step up your game with advanced wood joints. These joints require more skill and precision but offer greater strength and aesthetic appeal. Let’s explore some of the more intricate joints that can elevate your woodworking projects.

Mortise-and-Tenon Joint

The mortise-and-tenon joint is a hallmark of fine woodworking. It consists of a tenon (a protruding piece of wood) fitting snugly into a mortise (a corresponding cavity). This joint is renowned for its strength and is widely used in furniture making and carpentry.

To make a mortise-and-tenon joint, you’ll need to carefully measure and cut the tenon and the mortise so they fit tightly. This joint excels in load-bearing applications, such as in chair legs or table frames. While it requires more skill to execute properly, the resulting joint is incredibly strong and, if done correctly, can last for generations.

Dovetail Joint

The dovetail joint, known for its resistance to being pulled apart, is a go-to for drawers and boxes. The interlocking design of ‘tails’ and ‘sockets’ offers both strength and visual appeal. It’s a joint that signals craftsmanship and attention to detail.

Making a dovetail joint involves cutting a series of angled cuts that fit together tightly. Precision is crucial here, as the fit needs to be snug for the joint to hold effectively without glue. While challenging, mastering the dovetail joint adds a level of professionalism to your work that is hard to match with other joints.

Box Joints and Dovetail Variants

Box joints and dovetail variants, like the half-blind dovetail, offer alternatives to the classic dovetail joint. These joints are ideal for box and drawer construction, where strength and appearance are important. Box joints, with their square fingers, are simpler to make than dovetails but still provide considerable strength.

The half-blind dovetail, a variant where the tails are hidden on one side of the joint, is perfect for drawer fronts where you want the look of a smooth, uninterrupted surface. These variants require precise cutting and fitting, but the result is a strong and attractive joint that adds a professional touch to your projects.

Specialty Joints

Beyond the basics and the advanced, there are specialty joints that offer unique solutions for specific woodworking challenges. These joints may require specialized tools or techniques but can provide superior strength and aesthetic appeal in the right applications. Let’s delve into some of these specialized joints.

Sliding Dovetail

The sliding dovetail joint is a versatile and strong joint used in a variety of woodworking applications. It consists of a dovetail-shaped tenon sliding into a corresponding groove. This joint is ideal for shelves, partitions, or drawer fronts, where a strong, interlocking connection is needed.

Creating a sliding dovetail requires precision in cutting both the dovetail and the groove. The joint allows for a seamless and smooth connection, which is aesthetically pleasing and structurally sound. Though it may be challenging to master, the sliding dovetail is a valuable addition to your joinery skills.

Rabbet Joint

A rabbet joint involves cutting a recess into the edge of a piece of wood to accept another piece. This joint is commonly used in cabinet making and for joining panels. It provides a clean and strong connection, especially when combined with glue or fasteners.

To create a rabbet joint, you’ll need to accurately cut the recess to fit the joining piece. This joint is particularly useful in cases where a flush and neat finish is required. It’s a straightforward joint but offers a high level of precision and strength, making it a staple in woodworking.

Corner Bridle and Mitered Bridle Joints

The corner bridle and mitered bridle joints are variations of the traditional mortise and tenon joint, used primarily for frames and structural connections. These joints provide a strong and visually appealing connection, ideal for frames or where two pieces meet at an angle.

The corner bridle joint involves cutting a tenon on one piece and a corresponding mortise on the other, much like a traditional mortise and tenon, but with an open corner. The mitered bridle joint is similar but involves mitered cuts, offering a more aesthetic finish. Both joints require precision but provide a strong and elegant solution for angled connections.

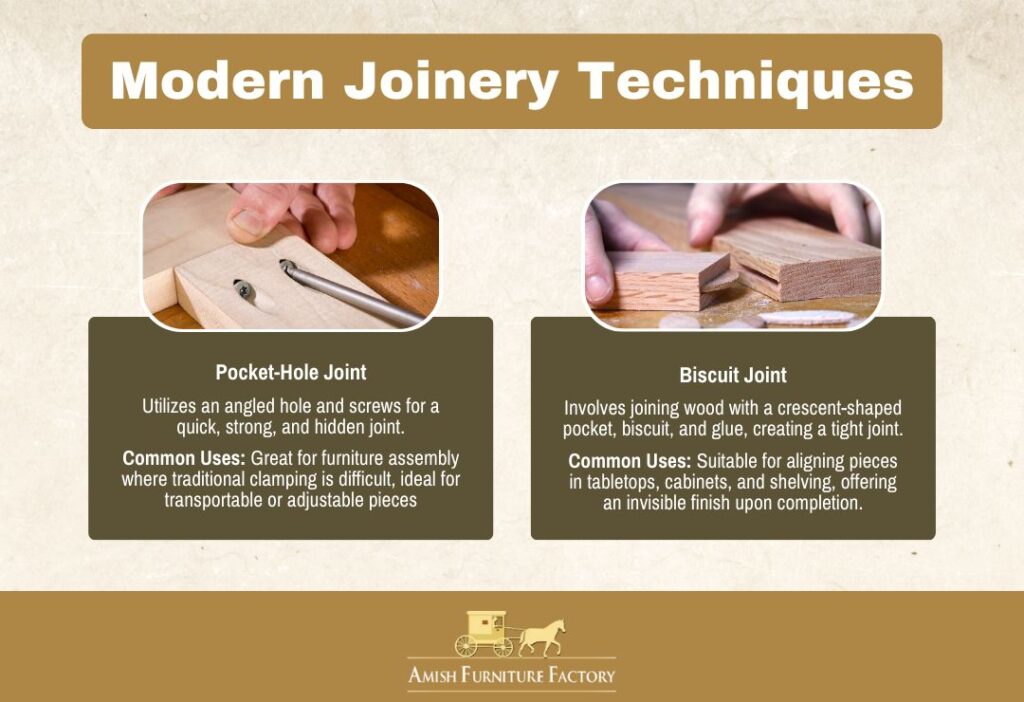

Modern Joinery Techniques

As woodworking evolves, so do the techniques we use to join pieces of wood. Modern joinery methods may not have the ancient pedigree of traditional joints, but they offer simplicity, efficiency, and reliability that are perfect for today’s fast-paced world. Whether you’re a prepper building sturdy, reliable structures or a hobbyist working on a weekend project, these modern techniques are invaluable.

Pocket-Hole Joint

The pocket-hole joint is a favorite among woodworkers for its simplicity and strength. It involves drilling an angled hole into one piece of wood and then joining it to another piece with a screw. This method is not only quick but also creates a strong and hidden joint, perfect for many applications.

You’ll find pocket-hole joints particularly useful in situations where traditional clamping is difficult. They allow for rapid assembly and disassembly, making them ideal for furniture that might need to be transported or adjusted. Additionally, the screws can be easily hidden with wooden plugs, maintaining a clean look. It’s a practical, no-fuss solution that delivers reliable results.

Biscuit Joint

Biscuit joints are another modern marvel in woodworking. They involve creating a crescent-shaped pocket in two pieces of wood and then joining them with a biscuit and glue. The biscuit, made from compressed wood, expands as it absorbs the glue, creating a tight and strong joint.

This technique is great for aligning pieces of wood, like when forming tabletops, cabinets, or shelving. It’s not as strong as some traditional joints, but its ease of use and the ability to align pieces precisely make it a popular choice. The invisible nature of the joint once the piece is finished adds to its appeal, keeping the focus on the wood’s natural beauty.

Choosing the Right Joint for Your Project

Selecting the right wood joint is crucial in ensuring the stability, durability, and aesthetics of your project. Whether you’re building furniture, creating a storage space, or crafting a decorative piece, the joint you choose plays a pivotal role. Understanding the balance between form and function is key in making the right choice.

Selecting Wood Joints Based on Aesthetics and Functionality

When choosing a wood joint, consider both its aesthetic impact and functionality. Some joints, like dovetails, are celebrated for their beauty and can be a feature in the design. Others, like butt or lap joints, are more utilitarian and may be better suited for internal structures or areas not in plain sight.

The choice of joint can also reflect your project’s style. For instance, a rustic piece might benefit from the visible, rugged look of a rabbet or bridle joint, while a more refined piece might call for the elegance of a miter or mortise-and-tenon joint. Remember, the joint is not just a means of connection; it’s an integral part of your project’s overall design and character.

How to Choose the Appropriate Joint

When it comes to load-bearing projects, the strength of the joint is paramount. Mortise-and-tenon or dovetail joints are often preferred for their inherent strength and ability to withstand stress. For shelving or cabinetry that need to support weight, these joints can provide the necessary durability and stability. It’s also important to consider the direction of the load and the type of stress the joint will face. A well-crafted joint not only supports weight but also withstands wear over time.

Tools and Techniques for Effective Joinery

Equipped with the right tools and techniques, you can tackle any joinery project with confidence. Whether you’re a beginner or an experienced woodworker, understanding the essentials and honing your skills is key. Let’s look at the tools and techniques that will help you create strong, precise, and beautiful wood joints.

Essential Joinery Tools for Woodworkers

Every woodworker needs a solid set of tools to execute joints effectively. At the very least, your toolkit should include a quality saw, chisels, a mallet, and a marking gauge. These tools are the bread and butter of traditional joinery and are indispensable for precise cuts and fitting.

In addition to these basics, consider investing in a good quality router and a set of bits for more complex joints like dovetails or mortises. A reliable drill, with a variety of bits, is essential for modern joinery techniques like pocket-holes and biscuit joints. Remember, the quality of your tools can greatly affect the outcome of your joints, so choose wisely and maintain them well.

Expert Tips for Precise Wood Joints: Techniques and Tools

Precision is the cornerstone of effective joinery. Always take accurate measurements and mark your cuts clearly. A common saying among carpenters, “Measure twice, cut once,” holds true in joinery. Rushing through this step can lead to ill-fitting joints and weakened structures.

Another tip is to keep your tools sharp. Dull tools not only make your job harder but can also compromise the precision of your joints. Lastly, don’t underestimate the importance of practice. Like any skill, joinery improves with repetition. Experiment with different joints, learn from your mistakes, and don’t be afraid to challenge yourself with more complex projects.

Common Challenges and Solutions in Wood Joinery

In woodworking, encountering challenges is a natural part of the process, but knowing how to address them effectively can make all the difference in your projects. Below is a list of some common joinery challenges you might face, along with practical solutions to help you overcome them and achieve the best possible results.

Challenge #1: Misalignment of Joints

Solution: Ensure accurate measurements and markings before cutting. Use a square to check the alignment during the assembly process. If necessary, adjust the cuts or gently use a mallet to align the pieces properly.

Challenge #2: Weak Joint Strength

Solution: Choose the right type of joint for the load it needs to bear. Reinforce the joint with adhesives, screws, or dowels if necessary. Ensure that the wood is properly prepared, and the joint fits snugly before assembly.

Challenge #3: Aesthetic Issues with Visible Joints

Solution: For joints that will be visible, select a joint type that complements the overall design. Carefully sand and finish the joint to make it as seamless as possible. Consider using decorative techniques like inlays to turn the joint into a design feature.

Challenge #4: Difficulty in Cutting Precise Joints

Solution: Use sharp, well-maintained tools for accurate cuts. Practice cutting on scrap wood before working on the actual pieces. Consider using jigs or templates for complex joints like dovetails.

Challenge #5: Wood Splitting When Joining

Solution: Pre-drill holes for nails or screws to prevent splitting. Avoid forcing the joint together; if it’s too tight, slightly adjust the size. Choose the appropriate type of wood for the specific joint to reduce splitting risk.

Challenge #6: Glue Squeeze-Out or Excess Adhesive

Solution: Apply glue sparingly and evenly. Wipe off any excess glue immediately with a damp cloth. For a cleaner finish, consider using masking tape around the joint area before gluing.

Challenge #7: Joint Gaps Due to Imperfect Cuts

Solution: Double-check measurements and use precise marking tools. If gaps are present, use wood filler that matches the wood color. For future projects, improve cutting techniques and consider using finer blades or higher quality saws.

Challenge #8: Time-Consuming Joint Construction

Solution: Plan your project carefully and prepare all materials beforehand. Practice more efficient techniques like batch cutting. Consider using simpler or more modern joinery methods where appropriate.

Final Thoughts

Wood joinery is both an art and a craft, requiring patience, precision, and practice. As Michael Dunbar insightfully put it, “Woodworking is a most satisfying pastime, so varied and multifaceted you will never complete the twin processes you have undertaken: acquiring tools and learning how to use them. You have begun a lifetime pursuit.” Whether you’re building for durability or crafting for beauty, the joints you choose play a crucial role in your project’s success.

By understanding the different types of joints, their applications, and the tools required, you’re well on your way to creating strong, beautiful, and lasting wooden structures. Remember, each joint tells a story of functionality and design, so choose wisely and craft with care. Happy woodworking!