Amish woodworking is widely respected for its precision, durability, and timeless appeal. Rooted in tradition and guided by strong values of simplicity and craftsmanship, Amish woodworkers rely on techniques that have been refined over generations. Their approach emphasizes careful planning, skilled handwork, and a deep understanding of natural materials rather than speed or mass production.

Key Takeaways:

- Amish woodworking techniques emphasize durability and precision using hand tool utilization, structural joinery, steam bending, detailing, and using natural finishes.

- Traditional Amish woodworking tools include hand planes, chisels, saws, and scrapers.

- The Amish meticulously prepare wood by seasoning it and hand-finishing pieces for long-lasting results.

In this article, we examine the woodworking techniques used by Amish artisans and explain how these methods contribute to the strength, beauty, and long-lasting quality of their work.

How Amish Techniques Compare to Modern Woodworking Methods

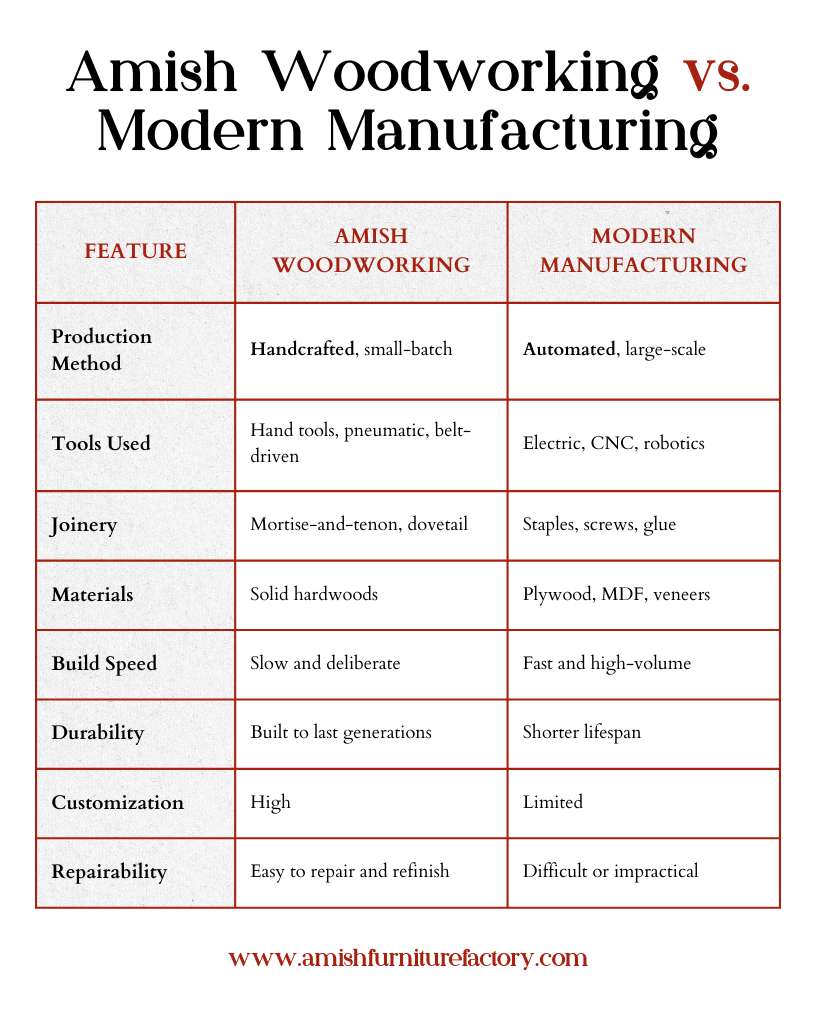

Amish woodworking techniques prioritize craftsmanship, durability, and hands-on precision, with each piece built slowly and intentionally by skilled artisans. Traditional joinery, solid hardwood construction, and extensive use of Amish woodworking tools result in furniture designed to last for generations, not just years. In contrast, modern woodworking methods often emphasize speed and efficiency. They rely heavily on automated machinery, engineered wood products, and fasteners to meet mass-production demands.

While modern manufacturing excels at affordability and uniformity, it frequently sacrifices longevity and repairability. Amish-built furniture stands out for its structural strength, attention to detail, and timeless appeal. Whereas, factory-made pieces focus on rapid output and trend-driven designs.

Understanding Amish Woodworking Techniques

A remarkable blend of age-old techniques and a deep reverence for the natural world are the most prominent characteristics of Amish woodworking. Here are some special techniques by the Amish furniture makers, Amish carpenters, and Amish woodworkers in their woodcrafting endeavors:

Strategic Wood Selection and Preparation

Wood selection and preparation are critical steps in Amish woodworking. The quality of the raw material directly affects strength, appearance, and longevity. Amish craftsmen carefully choose hardwood species based on grain pattern, hardness, and intended use. This ensures each piece performs well structurally and aesthetically.

Hand Tool Utilization

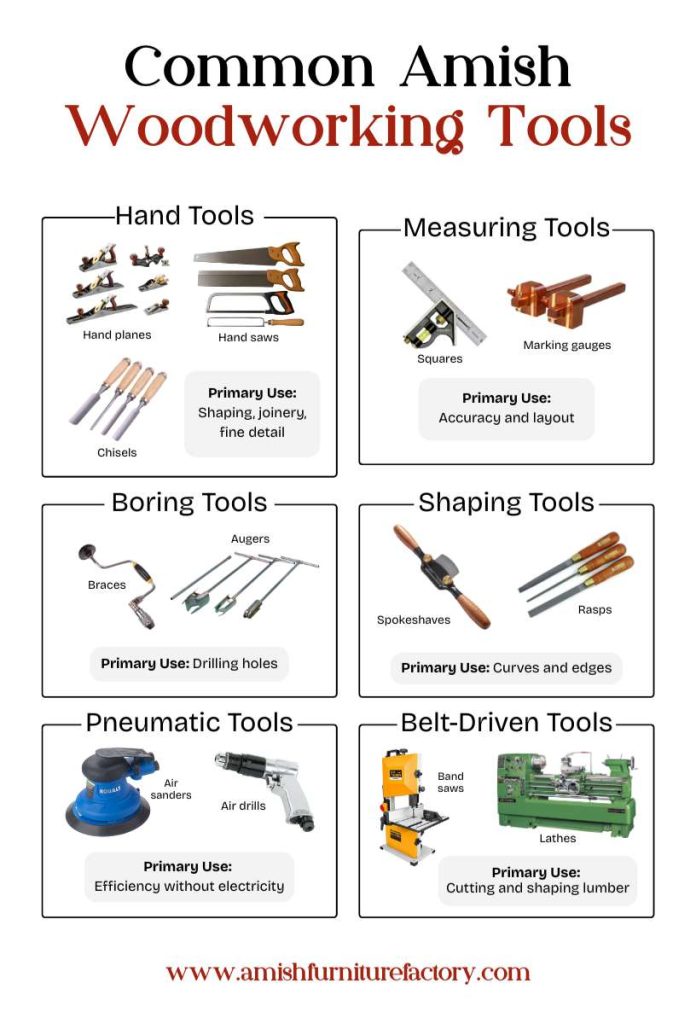

The Amish furniture makers and Amish carpenters rely extensively on hand tools rather than power tools. They skillfully use planes, chisels, saws, and scrapers to shape, smooth, and refine solid wood surfaces. This practice allows for greater precision and control while emphasizing the tactile connection between the Amish and the materials.

Structural Joinery

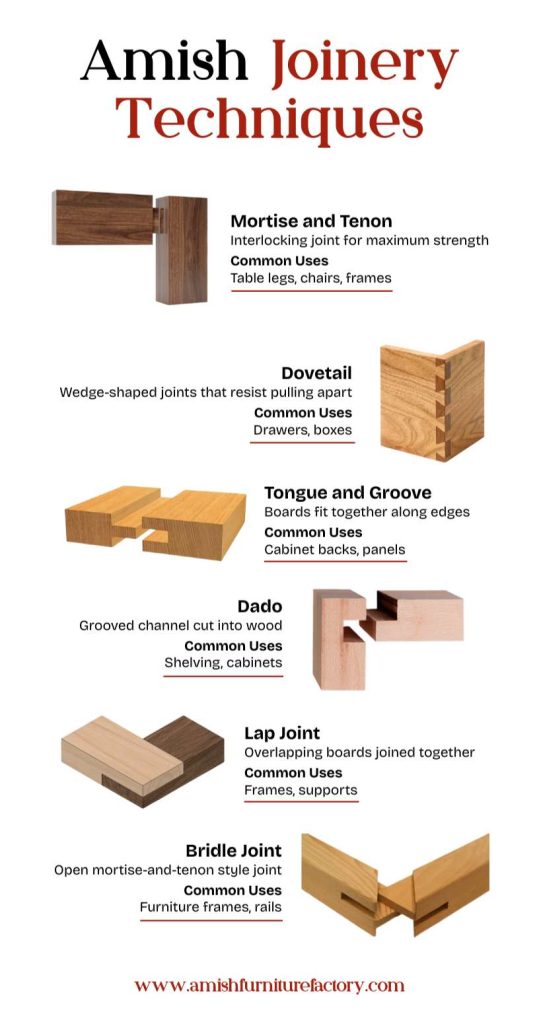

Joinery is a vital technique woodworkers from Amish communities employ to create strong, durable, visually appealing connections between wooden components without relying on nails or screws. Amish joinery techniques are time-honored and often passed down through generations. This contributes to the longevity and structural integrity of their woodworking projects.

Steam Bending

Steam bending is a remarkable technique by Amish furniture makers and woodcrafters to shape wood into graceful curves and bends. The entire task of steam bending starts with selecting a suitable piece of wood. The wood is cut into long, thin strips or boards slightly wider than the final shape. These strips are then put in a steam box. Once sufficiently steamed, the wood is carefully removed from the steam box and immediately placed into a bending form or jig. As the wood cools and dries, it hardens into the new curved shape, permanently retaining the desired form.

Hand Carving, Shaping, and Detailing

Hand carving, shaping, and detailing are what give Amish furniture its distinctive character and handcrafted appeal. Skilled artisans use chisels, gouges, spokeshaves, and hand planes to shape edges, legs, and decorative elements with precision. Unlike machine-cut designs, hand-carved details allow for subtle variations that make each piece unique. By relying on hand techniques rather than automation, Amish craftsmen maintain full control over the final form and finish.

Hand Sanding and Meticulous Finishing

Hand sanding and finishing is a crucial stage in Amish wood crafting. It involves refining the wood’s surface through careful sanding and applying various finishing techniques to enhance its appearance and protect it from wear and tear. This meticulous technique ensures a smooth, polished finish that accentuates the wood’s raw beauty. This also showcases the artisan’s attention to detail. Finishing techniques vary but often involve applying natural oils, waxes, or shellac to the wood’s surface.

Ready to put these techniques into practice? Read our comprehensive woodworking guides to access step-by-step blueprints and expert project plans.

Tools Used in Amish Woodworking and Craftsmanship

Amish woodworking tools reflect a balance between tradition, practicality, and community guidelines. Commonly used tools include hand planes for smoothing surfaces, chisels for joinery and detailing, hand saws for accurate cuts, and braces for drilling. These tools enable careful shaping and fitting, which are essential for strong joints and long-lasting furniture.

In addition to hand tools, many Amish workshops use non-electric, belt-driven, or pneumatic tools. These are powered by compressed air, water, or diesel engines. These tools increase efficiency without compromising craftsmanship or violating religious restrictions on electricity. Equipment such as air-powered sanders, drill presses, and band saws are used selectively. The final fitting and detailing are still by hand.

Conclusion

The Amish woodworking tradition, together with the world-renowned Amish furniture, is a testament to the enduring power and quality of Amish craftsmanship and the deep connection between artisans and their materials.

Through their unwavering dedication to hand tool utilization, joinery techniques, steam bending, hand carving, and meticulous hand sanding and finishing, the Amish have sharpened their woodworking skills to build furniture and even homes that are considered by many as timeless pieces of artistry. The commitment of every Amish community to simplicity, tradition, and the inherent beauty of natural materials is evident in each meticulously crafted wooden creation.

Frequently Asked Questions

How do the Amish cut wood?

The Amish cut wood using a combination of hand saws, band saws, and circular saws. These are run by belt-driven or pneumatic systems rather than conventional electricity. Final cuts and fitting are often by hand to ensure precision.

Do Amish use screws?

Yes, Amish woodworkers use screws sparingly and strategically. While they rely on traditional joinery for primary structural joints, they typically apply screws where the piece requires reinforcement or future disassembly.

How long does it take the Amish to build a piece of furniture?

Depending on the size and complexity, a single piece can take anywhere from several days to several weeks. Custom furniture and intricate designs require additional time due to hand craftsmanship and finishing.

What is the difference between “Amish-style” and authentic Amish-made furniture?

“Amish-style” furniture is mass-produced and inspired by Amish designs, often using machinery and shortcuts. Authentic Amish-made furniture is by Amish artisans using traditional techniques, solid hardwoods, and time-tested joinery.

Do Amish woodworkers use glue and nails, or is it strictly wood-on-wood joinery?

Amish craftsmen do use wood glue to strengthen joints and may use nails in non-structural areas. However, the core strength of the furniture comes from wood-on-wood joinery such as mortise-and-tenon and dovetails.