When you invest in Amish furniture, you’re not just buying a table, chair, or dresser—you’re bringing home a piece of craftsmanship rooted in generations of tradition. Known for its solid wood construction and timeless design, Amish furniture deserves a finish that both protects and enhances its natural beauty. But with so many finishing options out there, how do you know which one is best? Whether you’re looking for a glossy sheen, a soft satin look, or a finish that stands up to everyday wear and tear, choosing the right one is key to preserving your furniture for years to come.

Key Takeaways:

- The best furniture finish for Amish furniture is catalyzed conversion varnish, especially when professionally applied.

- Other options like lacquer, polyurethane wood finish, shellac, and oil/wax finishes each offer distinct advantages depending on use, look, and maintenance needs.

- Choose a finish based on how the furniture will be used, where it will live, and how much upkeep you’re willing to do.

In this article, we’ll explore the most popular finishes used on Amish furniture, what makes each unique, and how to pick the best one for your home and lifestyle.

Why Furniture Finishes Matter (and What’s Actually in Them)

A good furniture finish plays a crucial role in protecting the wood, especially when it comes to Amish furniture made from solid hardwoods. The right finish acts as a shield against everyday threats like heat, moisture, spills, dust, and the occasional bump or scratch, helping the piece last for generations. At its core, a furniture finish has two main purposes: to preserve the wood and to highlight its natural beauty. The type you choose impacts not only how the furniture looks and feels, but also how well it wears over time.

Most finishes—whether classic oils or modern varnishes—are built from three main components:

- Resin: This is the tough stuff that forms the actual protective layer. Think of it like armor for your furniture.

- Solvent: Helps apply the finish smoothly and then evaporates as it dries.

- Additives: These tweak the formula to improve things like drying time, durability, or UV protection.

One more factor that’s easy to overlook but makes a big difference: sheen level. That’s the amount of shine or gloss in the finish, and it changes both how the piece looks and how much wear it shows over time.

Mike Aziz, a veteran real estate investor with 20 years of experience rehabbing and staging homes, shares:

“Working with houses to sell, I’ve found that prospective buyers always prefer Amish furniture with satin finishes over high-gloss. Why? It’s practical: satin finishes on oak and cherry cover fingerprints and repair minor scratches, but high-gloss finishes highlight every imperfection.”

How Wood Type Influences Finish Choice

Not all hardwoods behave the same way when it comes to finishing. In Amish furniture, where species like oak, cherry, maple, and walnut are commonly used, the choice of wood plays a major role in how a finish looks, feels, and even performs over time. Different woods have different levels of porosity. For instance, red oak has an open grain that soaks up stains quickly and shows dramatic contrast. Grain pattern also influences finish choice. Woods with strong, visible grain—like quarter-sawn white oak—benefit from finishes that enhance texture and depth. Then there’s natural color. As Aziz notes:

“The type of wood dictates the optimal finishing technique. Cherry ages its deep patina independently of finish, but I’ve found that applying lighter initial coats of finish allows for a more dramatic color shift with age… Oak is more porous and reacts to grain-filling techniques before top coating… walnut pieces with hand-rubbed oil finishes must be refinished every 18–24 months, while the same wood with a high-quality lacquer lasts 8–10 years.”

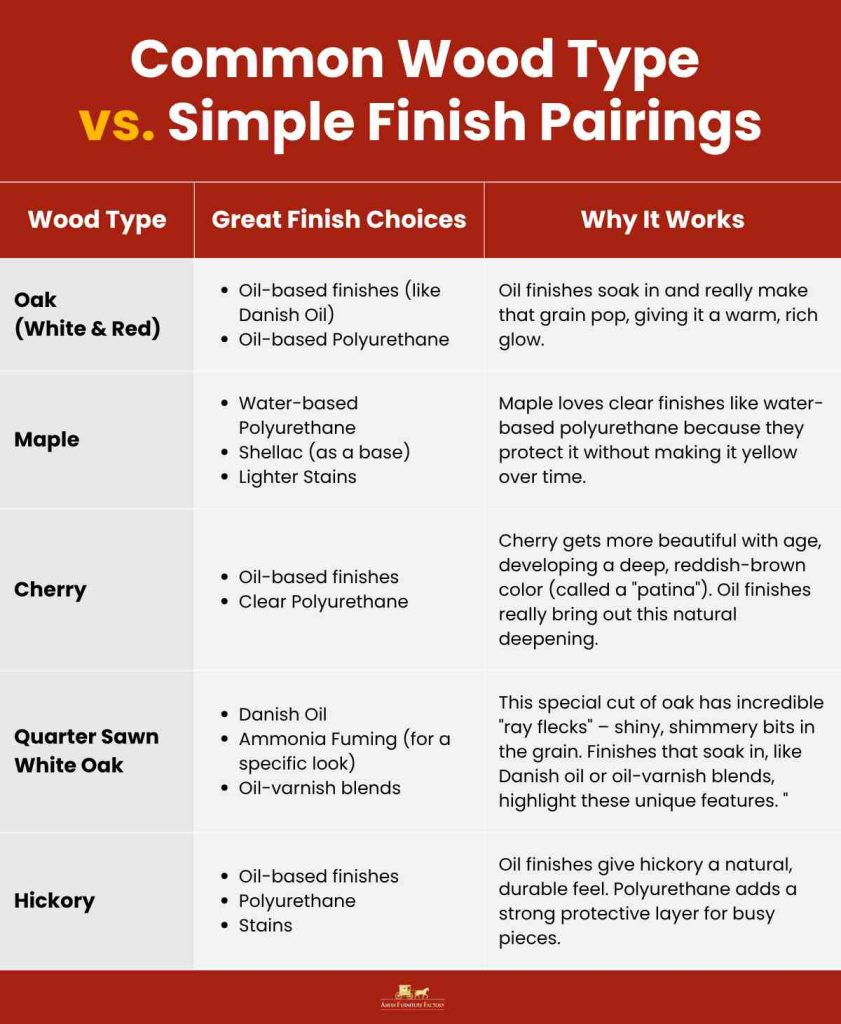

Here’s a guide for common types of wood vs. simple finish pairings.

The Best Furniture Finish for Amish Furniture

The best furniture finish for Amish furniture in terms of durability, appearance, and overall performance is the catalyzed conversion varnish. This finish is engineered to be tough and holds up beautifully against heat, moisture, everyday wear, and even some chemical exposure. Other top choices include the lacquer, polyurethane (both oil- and water-based), shellac, and traditional natural oil or wax-based options.

Each type of wood finish has its strengths—and knowing how they compare can help you choose the right one for your needs and lifestyle. Let’s explore in detail.

Catalyzed Conversion Varnish

Catalyzed conversion varnish is a durable, two-part finish commonly used on high-quality Amish furniture. It offers excellent protection against water, heat, moisture, stains, and abrasions, making it perfect for everyday-use pieces like dining tables and desks.

Lacquer (Nitrocellulose & Acrylic)

Lacquer is a timeless finish that enhances hardwoods like cherry and walnut with its quick-drying properties and rich tone. Nitrocellulose lacquer delivers a warm finish, while acrylic lacquer is UV-stable and maintains its clarity over time. Aziz emphasizes the durability of certain lacquer finishes.

“Catalyzed lacquer is the finish of choice for Amish furniture in high-use areas. Based on my property restorations, I’ve observed that Amish furniture refinished with catalyzed lacquer maintains its finish 3-4 times longer than oil-based finishes on rental homes and family homes.”

Oil-Based & Water-Based Polyurethane

Polyurethane finishes are commonly used in both mainstream and Amish furniture, especially when specific durability or budget needs arise. Oil-based polyurethane provides a rich amber tone and durability, while water-based polyurethane dries fast, remains clear, and has lower VOCs.

Shellac

Shellac is a natural resin finish that has been used for centuries and is loved for its warm, historical appeal. It dries quickly, giving wood a glowing sheen that deepens color and highlights the wood’s figure, often seen in antique or period-style Amish furniture.

Natural/Oil and Wax Finishes (e.g. Tung, Linseed, Milk Paint)

Natural finishes like tung oil, linseed oil, and beeswax are still used by some Amish craftsmen who prefer traditional, sustainable methods. These finishes soak into the wood, enhancing its natural feel and giving it a rich, organic luster.

Caitlin Agnew-Francis, the Manager at Desky, specializing in furniture and workspace solutions, offers valuable insights:

“Because they can penetrate the wood and provide exceptional longevity while maintaining the original grain, oil-based finishes are the preferred option for Amish furniture. For hardwoods like oak and cherry, tung oil works especially well because it resists moisture and gives the wood a deep, rich look.”

Ready to give your Amish furniture the perfect look? Explore our top-rated wood stains and finishes to enhance its natural beauty and durability.

Which Finish Works Best?

When choosing the best finish for Amish furniture, it’s helpful to go beyond just how it looks. You want to know how it actually holds up in real life. That’s where performance testing, environmental ratings, and industry durability standards come into play. In professional environments like hospitality or commercial spaces, durability is often measured using SATRA standards, which assess a finish’s resistance to scratches, water, heat, and chemicals. While Amish furniture isn’t always subjected to these formal tests, the same criteria can still be used to assess how well each finish performs in the home.

Here’s how the most popular Amish furniture finishes measure up in key performance areas:

How to Choose the Best Finish

Choosing the right finish for Amish furniture starts with how you plan to use the piece. A dining table that sees daily meals and the occasional spill needs something tough—catalyzed conversion varnish is usually the go-to for that level of protection. On the other hand, a decorative cabinet or bedroom nightstand might not need such industrial durability and could benefit from the softer, more traditional look of lacquer or even natural oil finishes.

Aesthetics matter, too. Some finishes add warmth, others keep the wood’s color crisp and clear. If you want to preserve a light maple or ash, avoid oil-based finishes that amber over time. If you’re working with cherry or walnut, a clear coat or hand-rubbed oil might be just enough to showcase its natural depth. And don’t forget about maintenance. Some finishes are practically set-it-and-forget-it, while others (like wax or oil) require occasional reapplication.

Easy Guide to Applying Finishes (for DIYers and Craftsmen)

As Mike, an experienced professional, shares the significant impact that proper application has on the longevity and performance of a finish:

“A professional application makes a 300% difference in life. I’ve learned this through costly mistakes at the start of my investment career. Factory-applied finishes always outlast field applications, with professional spray-booth lacquer lasting 15-20 years and brush-applied alternatives lasting 5-7 years.”

Here’s a simple guide to help you through the finishing process:

1. Prepare the Entire Surface

Start by sanding the wood surfaces evenly, working up to 220-grit sandpaper for a smooth finish.

2. Choose the Right Finish for the Job

Match the finish to the wood type, intended use, and desired look. For example, wipe-on oils are easy for beginners, while polyurethanes offer a balance of durability and ease.

3. Apply the First Coat

Use a natural bristle brush, clean cloth, or sprayer, depending on the finish type. Wipe-on oils are applied with a cloth and polyurethane with a brush. Always follow the product’s directions for drying times.

4. Let It Dry Completely

Give the first coat enough time to dry—this can range from 30 minutes to 24 hours depending on the finish. Don’t rush this step, especially with oil-based products or humid environments.

5. Lightly Sand Between Coats

Once dry, lightly sand the surface with 320–400 grit sandpaper or a fine sanding pad to smooth out imperfections. Wipe clean before applying the next coat.

6. Final Buff or Polish (Optional)

For natural oil or wax finishes, buff the final coat with a clean cloth for a soft sheen. For harder finishes like polyurethane or lacquer, you can polish with fine steel wool and paste wax.

Conclusion: Choosing the Right Furniture Finish for Your Furniture and Lifestyle

When it comes to Amish furniture, the perfect finish is about honoring the craftsmanship and bringing out the natural character of the wood. From high-performance conversion varnishes to traditional oils and waxes, each option has its own strengths—just like the wood beneath it. If you’re investing in a handmade piece of Amish furniture, it’s worth taking a few minutes to think through how you want it to age, feel, and function.

Frequently Asked Questions

What is the best finish for antique furniture?

For antiques, shellac or natural oil finishes (like linseed or tung oil) are often the best choice. They’re historically accurate, easy to repair, and don’t drastically alter the wood’s character.

How do I protect my Amish furniture?

To keep your Amish furniture in top shape, avoid direct sunlight, extreme humidity changes, and placing hot or wet items directly on the surface. Use coasters, placemats, or protective pads when needed. Dust furniture regularly with a soft cloth, and avoid harsh cleaners.

What finish do Amish craftsmen typically use on hardwood furniture?

Most Amish craftsmen today use catalyzed conversion varnish for its long-lasting durability, moisture resistance, and clarity. It’s especially popular on dining sets, desks, and cabinetry.

How important are VOC levels when choosing a furniture finish?

VOC (volatile organic compound) levels affect indoor air quality and environmental impact. If you’re finishing furniture in your home or are sensitive to chemical odors, it’s best to choose low-VOC or zero-VOC options like water-based finishes, natural oils, or hard wax oils.

Can I change the natural finish on my existing Amish furniture, and what are the considerations?

Yes, but it takes careful planning. You’ll need to fully remove the existing finish through sanding or stripping before applying a new one. Consider the type of wood, the original finish, and whether the new finish is compatible.